Global Ethylene Platform

Identify, Pursue and Track Opportunities Associated With Maintenance Turnaround WorkGlobal Ethylene Platform

The Global Ethylene Platform helps identify, pursue, and track opportunities associated with planned and unplanned maintenance turnaround work for more than 395 operational ethylene production units. Subscriptions include access to project and plant platform information, unit profiles, and unit turnaround reports that are updated routinely on a strict quality-control schedule. Research for plant details, turnaround schedules and project activities are performed using our direct phone-verification methods to ensure accuracy of all platform information.

About the Industry

Ethylene is a global commodity with major production centers in Asia, Europe and the Americas. While ethylene was traditionally produced from naphtha feedstock, low cost NGL and methanol has enabled world scale capacity additions from a growing number of feedstock options. These changes in the industry, along with growing demand for polyolefins, will promote a significant amount of additional capacity over the next decade.

Plant and Unit Platform

The Ethylene Platform includes information on 265 global ethylene plants, with profiles on 335 production units. Plant information includes: owner and operator names, physical and mailing addresses, phone numbers, plant operations details, and functional management contacts. Unit details include: unit name, owner, operator, capacities, feedstock, technology and more.

Unit Turnaround Tracking

Subscribers have instant access to all planned and unplanned ethylene unit turnarounds within the platform, as well as access to our research staff for real-time rumor tracking. New turnaround information such as schedule updates and unit status are delivered as they are discovered. Turnaround data includes the scheduled start date and duration, combined with plant and unit details. When maintenance turnarounds occur in this industry, the spending is significant, mainly because most major ethylene plants commonly schedule turnarounds only once every few years. The average duration of a turnaround is 25 days, with an average cost exceeding $15 million or more.

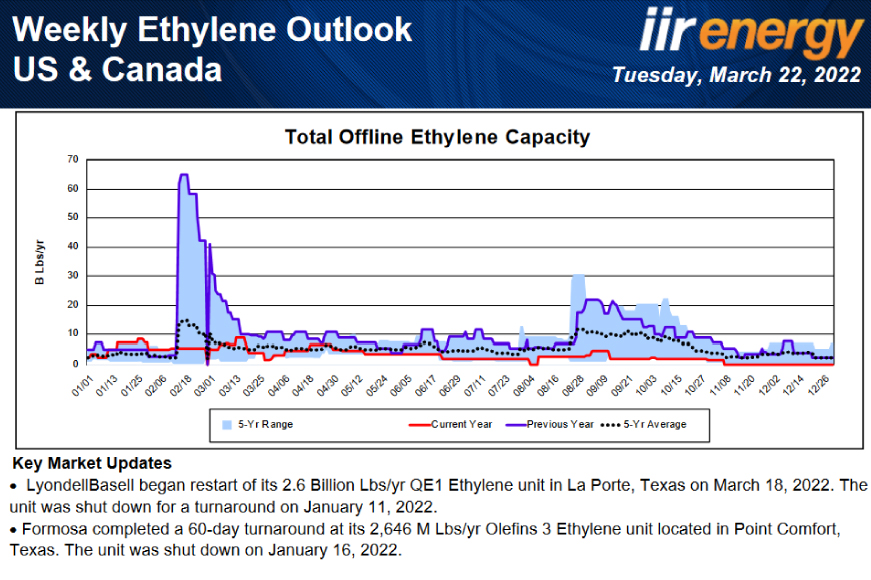

Weekly Ethylene Outlook

Each week Industrial Info's research teams summarize and publish an ethylene outlook report for each global region, providing timely insight market drivers and key market updates driving this very volatile industry. Access to this report is provided via a widget in IIR's online PECWeb tools. These reports include editorial comments on planned, unplanned and ongoing maintenance events, capacity startups and closures plus much more. This report includes charts and graphs for maintenance event moving averages, daily and weekly offline capacity summaries, a complete listing of all future maintenance events by global region, and new capacity forecasts based on active projects.

This report is available for the following world regions:

- USA & Canada

- Latin America

- South Asia & Middle East

- Europe & Russia

- East Asia (China, Japan & Korea)

Contact us today for more information on the platform!

Potential opportunities during these turnarounds are available for:

- Refractory

- Mechanical & Electrical Firms

- Inspection Services (X-ray and NDE)

- Instrument and Control Calibration

- Fabrication (Millwright) and Welders

- Hydroblasting

- Maintenance and Replacements

- Pumps, Motors, Valves

- Bearings, Seals, Piping

- Insulation, Columns, Compressors

- Tanks and Vessels

Platform Attributes:

- Turnaround coverage on 315 ethylene units at 395 plants

- More than 1,550 historical, current, and future outages

- More than 1,200 plant and unit contacts

- Start and end dates (duration) for each turnaround

- Platform updates are provided dynamically as changes are identified, including important new developments and schedule changes

- IntraDay Turnaround Alerts are sent immediately via email to ensure timely delivery of schedule changes or unplanned turnaround activity

- Analyze future and historic maintenance turnaround schedules